The fire detection units are used in the Fire Alarm System (FAS). The main purpose of the fire detection units is to detect fire, smoke, flame, and gas concentration and send the information of these detected parameters to the Fire Alarm Control Panel (FACP). The fire detection units are categorized as follows.

- Smoke Detector

- Heat Detector

- Carbon Monoxide Detector

- Multi-Sensor Detector

- Manual Call Point

1. Smoke Detector

The smoke detectors are used to detect smoke and installed in commercial buildings, schools, colleges, hospitals, railway stations, bus stations, industrial areas, residential areas, and others. The smoke detectors are powered by a FAS.

The smoke detectors are sub-classified as follows based on design and working principles.

a) Ionization Smoke Detectors:

Inside Ionization smoke detectors, two chambers are used.

The first chamber is called the compensate chamber and used to compensate for the changes in pressure or humidity or moisture or ambient temperature.

The second chamber has a small amount of radioactive material (alpha particles). Americium (Am) is a radioactive material with atomic number 95. It is used to generate alpha particles. The radioactive material is used to ionize the oxygen and nitrogen atoms of the passing air in the second chamber where current flows between two plates (called electrodes).

When the fire has happened, the smoke enters inside the chamber and the current flowing between two plates is reduced to threshold level or set-point and the fire alarm becomes enable. The signal conditioning circuit is used to enable fire alarm when the current drop between two plates is generated.

Compare to photoelectric smoke detectors, the ionization smoke detector is more sensitive and responsive to the flaming stage of fires.

b) Light Scattering Smoke Detectors:

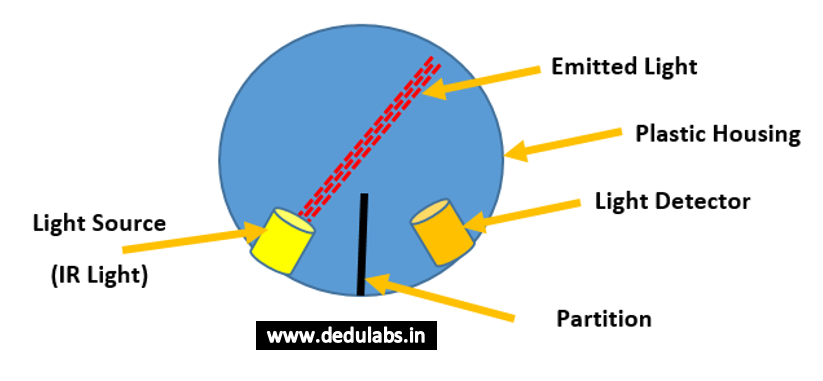

Fig. 1 presents the internal construction of a light scattering smoke detector without fire. A light source (IR LED, Laser Light, LED, and other) and light detector or photodetector (photodiode, phototransistor, LDR, and other) are attached in a darkened chamber area. The light source generates light rays. In this case, the light rays do not directly fall on the light detector. The light detector is interfaced with a fire alarm through a signal conditioning circuit. When no fire is detected, the detection circuit remains balance.

Fig. 2 presents the internal construction of a light scattering smoke detector with fire and smoke. When the fire is generated, the smoke enters in the detector chamber and this smoke distorts the environment inside the chamber. Due to smoke, scattering of the light rays takes place and this scattered light is falling on the photo-detector or light detector. Due to this, the electrical circuit becomes unbalance and enables fire alarm.

c) Light Obscuring Smoke Detectors:

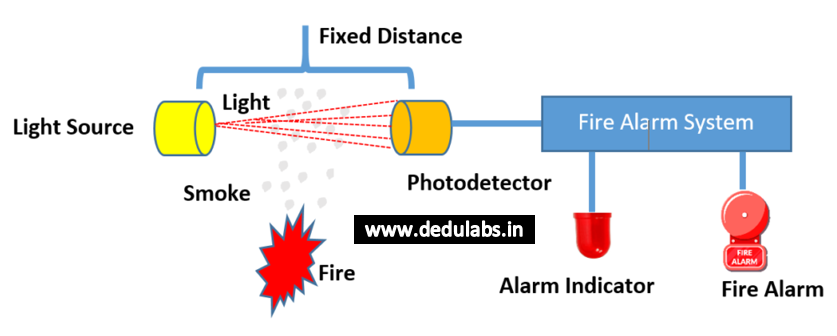

In the Light obscuring smoke detector, a light source, and light detector are installed at a fixed distance. The light source emits light rays. Initially, without fire and smoke, the light ray intensity falls on the photodetector is higher. When the fire is generated, due to smoke the light intensity falling on the light detectors is decreased. The light detector measures the amount of light intensity. The light detector or photocell or photodetector is interfaced with fire alarm and fire alarm indicator through a signal conditioning circuit. This variation in the light intensity receiving by a light detector is used to trigger the fire alarm and fire indicator.

2) Heat Detectors:

The heat detector is used to detect the temperature of a particular area where it is installed. The heat detectors are work based on a specific constant value of temperature or on the rate of change of temperature.

In the heat detector, the solid material, the eutectic alloy is used. The eutectic alloy is a heat-sensitive element to the specific temperature.

In the case of fire, the atmosphere temperature of the affected area is changed. When the affected area temperature is going beyond the set-point value or predetermined value or threshold limit, the eutectic alloy turns from a solid material to liquid form and turns ON the fire alarm.

3) Carbon Monoxide (CO) Detector:

The carbon monoxide (CO) detector is used to sense and measure the concentration amount of CO in the atmosphere. It does not detect the other combustion gas. The carbon monoxide, poisonous gas is generated by combustion. When the fire is generated and the concentration amount of carbon monoxide in the surrounding area is increasing above the threshold limit, the detector sends a message to the Fire Alarm System (FAS) for triggering the fire indicator and fire alarm. The carbon monoxide detector design for fire safety application is more sensitive and offer a faster response.

4) Multi-Sensor Detectors

The main purpose of this type of sensor is to detect the accurate conditions of the sensing area and reduce the probability of unwanted false alarm. Due to this, the verified true operations are performed. This sensor is used to sense the multi number of parameters like smoke, heat, CO, and light. Due to wide measuring capability, it is called as a multi-criteria alarm.

5) Manual Call Points:

The manual call point is a manual type fire detection method. The manual call point has a compact design with the glass and button. In case of fire or emergency conditions, the fire alarm circuit is triggered by breaking the glass or pressing a frangible element. For breaking of glass, only thumb pressure is enough and it does not require a hammer.

The criteria of installation of manual call points are

a) They are installed at a clearly visible and accessible position and mostly located at a height of 1.20 meter to 1.40 meters above the floor level.

b) They are installed on exit routes.

c) They are installed at the entry floor landings of staircases.

d) They are installed at all exits to the open air.

e) The distance between two manual call points is approximately 30 meters.

Users Today : 4

Users Today : 4 Total Users : 19341

Total Users : 19341 Views Today : 5

Views Today : 5